Hydraulic manifolds aren’t difficult to make, but you still want a manufacturing partner with powerful equipment, skilled machinists, and experience machining complex assemblies.

Throughout the US, engineers and OEMs trust Moseys’ precision machining services to turn their blueprints into high-quality hydraulic manifolds. Explore what makes our California machine shop ideal for your hydraulic manifold needs.

Hydraulic Manifolds: Overview

A hydraulic manifold is a metal housing that contains flow regulators, valves, solenoids, and other components. This distribution device controls fluid intake and output, directing the fluid between ports, pumps, actuators, and throughout the rest of the hydraulic system.

Put simply, a hydraulic manifold is the control box that pushes hydraulic fluid through a system’s carefully constructed pathways.

The Many Uses of Hydraulic Manifolds

Numerous industries use hydraulic manifolds, from aerospace to agriculture to industrial machinery. Hydraulic manifolds are standard in applications such as these:

- Airplane flaps, doors, and landing gear

- Tractors and forklifts

- Elevators

- Automobile braking and power steering systems

- Cargo lifts and winches

Anytime fluid is necessary for powering a system, you’ll find a hydraulic manifold working behind the scenes.

Manufacturing Hydraulic Manifolds

While our California machine shop doesn’t have a “top secret recipe” for making high-quality hydraulic manifolds, we have extensive experience with the myriad nuances inherent to hydraulic systems.

Materials

We most commonly make hydraulic manifolds from aluminum, steel, stainless steel, and cast iron, with aluminum alloy as the top choice for most Moseys customers.

Equipment

What’s the best CNC machining service for manufacturing hydraulic manifolds? Whatever gets the job done!

At Moseys, we leverage horizontal milling with pallet pool systems to make these intricate parts with minimal setups, meaning you benefit from improved accuracy and throughput on every part.

A hydraulic manifold’s precision callouts require specialized tools for accurately machining the box’s critical ports. Moseys’ horizontal mills have an impressive 240-tool capacity, allowing us to dial in repeat jobs quickly and keep lead times low.

Machining

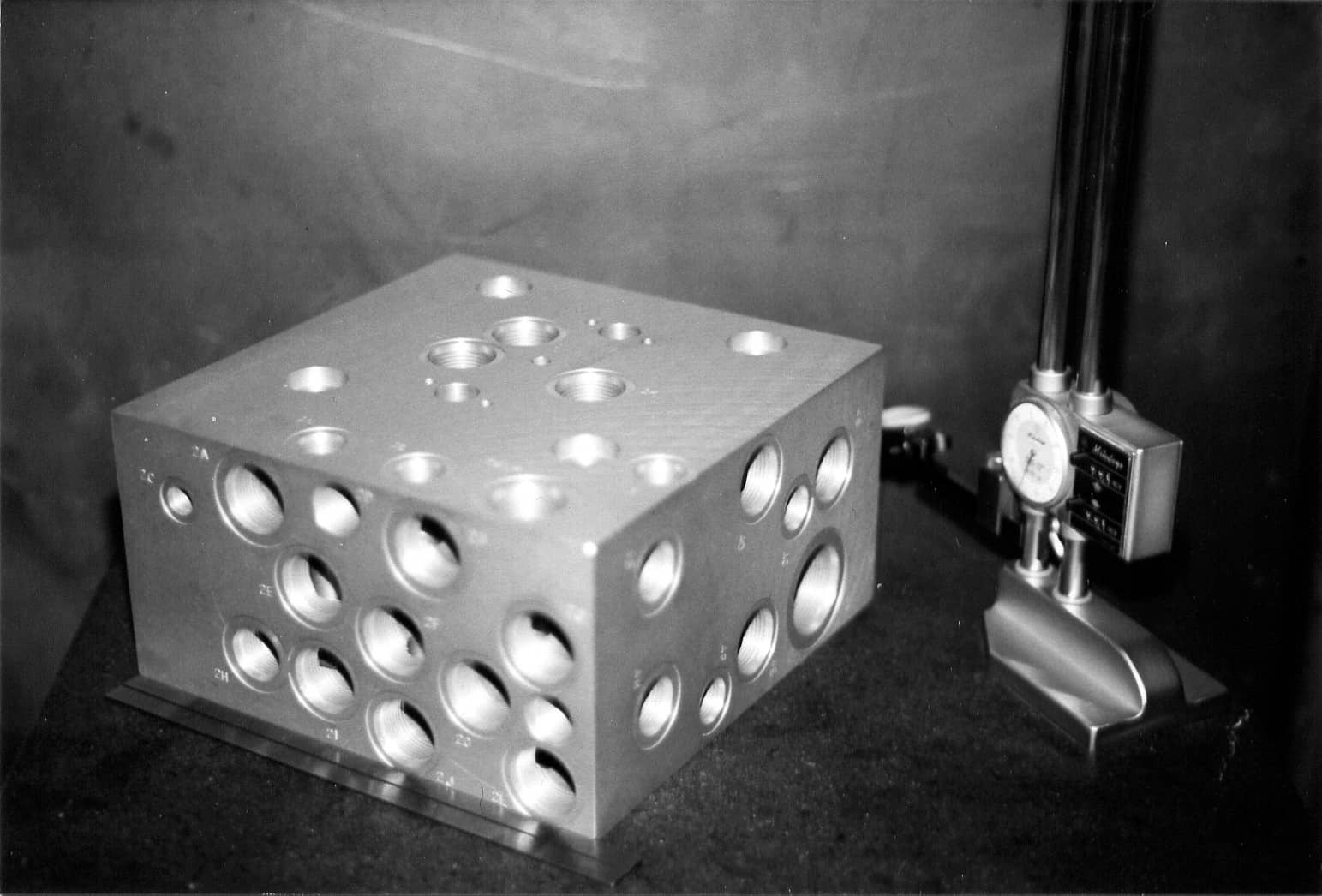

As we drill a hydraulic manifold’s many, many, MANY holes, what starts as a plain block of metal begins to resemble a chunk of Swiss cheese.

After drilling the rough holes, we utilize specialized port tools to finesse the correct port geometries before threading the ports according to our customer’s blueprint.

Finally, we laser engrave identification numbers or letters beside each hole. These marks provide a sort of external diagram for your assemblers, identifying each port’s input and output holes.

Deburring

After completing our CNC machining services, we deburr the hydraulic manifold. Deburring isn’t typically a complicated task, but it becomes quite a challenge when navigating a manifold’s many intersecting tunnels.

Surface finishes

Depending on the material and the application environment, we may add a protective coating to your hydraulic manifold. Chemical film and cadmium electroplating are the two processes we most commonly apply to them for finishing.

Many aviation customers require hydraulic manifolds with ground continuity. When these parts also need an electrically non-conductive anodize coating, we carefully mask the appropriate surfaces to prevent the oxide layer from forming across the entire manifold. We’re happy to support our customers’ safety protocols by ensuring their hydraulic manifolds can remain grounded.

Assembly

Though we don’t fully assemble all of a hydraulic manifold’s components, we do install leap plugs or port plugs wherever necessary.

Plugs are necessary in hydraulic manifolds with numerous intersecting holes that aren’t all meant to connect. When drilling multiple through-holes, avoiding previously drilled channels is often impossible. In other instances, we must drill access holes in order to reach a specific internal feature.

Whenever we’re forced to create unwanted access holes or intersections in a hydraulic manifold, we use permanent stoppers to plug those holes, preventing fluid leakage and improper flow.

Get Superior Hydraulic Manifolds from the Experts at Moseys

When you work with Moseys, you partner with an experienced hydraulic manifold manufacturer whose efficient, to-the-print precision machining services deliver incredible quality without lengthy lead times. Our nearly 50-year-old shop leverages top talent, excellent equipment, and a customer-first commitment to making hydraulic manifolds accurately and efficiently.