Here at Moseys, one of the ways we give our customers a positive manufacturing experience is by providing value. Far from meaning “cheap” or “sub-par,” value means making top-quality parts at the best possible price—and that requires us to procure superior materials for less.

How do we do it?

Bulk buying.

Learn how our California machine shop pre-purchases mill runs of high-demand materials to improve the price point on every precision CNC machining project.

The Advantages of Bulk Buying Material

Like any good business, we negotiate pricing with our vendors whenever appropriate, and buying material in bulk is one of the best ways to keep costs low—ours and yours!

Many of our material vendors permit us to lock in a bulk-order price without requiring us to receive the mill run all at once. Instead, these vendors ship smaller, consumable-size batches of the material over time and allow us to pay as we go—a big perk for our accounting processes!

And because the material deliveries are spaced out, we don’t have to overwhelm our California machine shop’s inventory storage with huge quantities.

Thanks to our bulk purchasing agreements, the material you need is always available exactly when you need it—no more lengthy lead times as you wait for the supply chain to catch up with your production needs!

Planning to avoid delays

It’s important to note that we still need to plan to avoid potential delays. Because suppliers tool and process their materials one batch at a time, we can wait several weeks for a completed mill run as the supplier finishes other batches. However, this concern isn’t too serious since we anticipate delays and place our material orders in advance when possible.

Your Blanket Orders Inform Our Bulk Purchases

Blanket ordering is the customer’s version of bulk buying. When you place a blanket purchase order for a year’s worth of parts, we gain a clear picture of your material needs for the coming months. With this insight, Moseys will bulk buy the necessary materials well in advance.

Just as bulk buying secures our shop’s material pricing up front, blanket ordering secures your part pricing up front. Together, these methods ensure consistent parts at the best possible price.

Material Matters

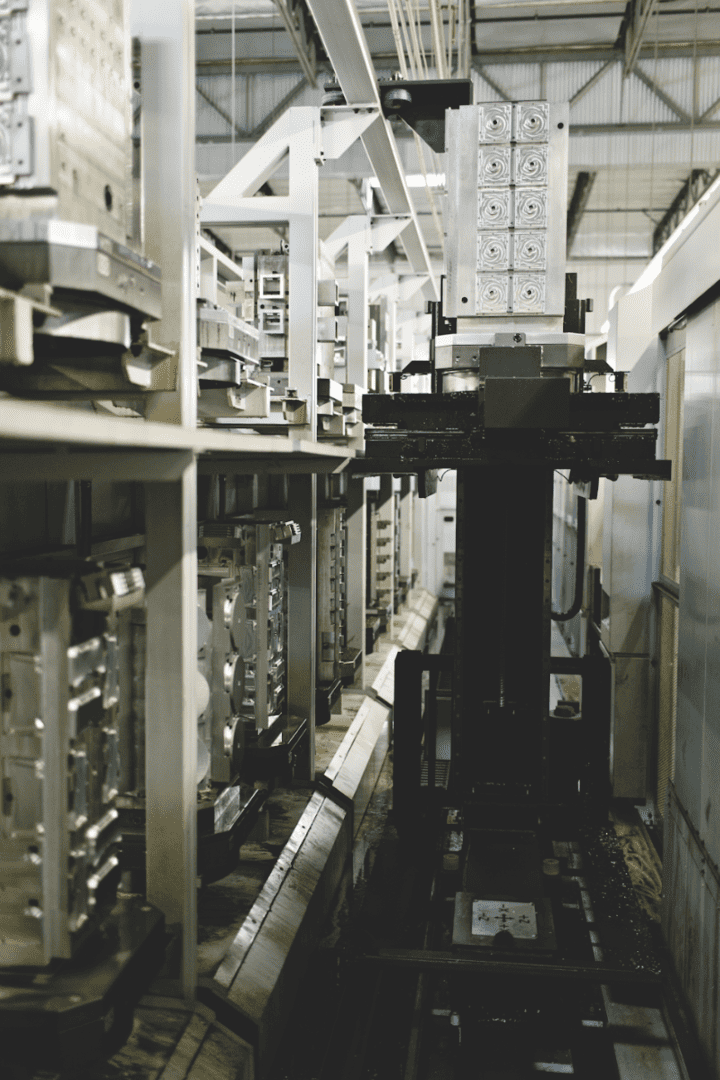

Our production machining services flow seamlessly thanks, in large part, to our material procurement methods. Every precision CNC machining customer deserves short lead times and great prices, and those benefits are only possible because we take the steps necessary to maintain a reliable inventory of top materials.

Before placing your next Moseys order, talk to our team about solutions for your specific parts. We’ll discuss your material options, lead time considerations, and blanket ordering possibilities—all with the end goal of delivering exceptional quality and great value.

Are you already set up for success with our California machine shop? Go ahead and get a quote!