As manufacturing costs increase across precision machine shops to fulfill a high demand, Moseys is committed to maintaining a competitive advantage. While factors like wage inflation, secondary processing costs, and material costs may be outside our control, we can control how we contain costs at our Anaheim machine shop.

Specifically, we’re leveraging robotics and automation to offer lights-out production machining, meaning our shop can run 24 hours a day, seven days a week, with a lean team. This approach allows us to achieve a high output of parts with minimal labor costs, which helps keep customers’ prices from rising significantly.

Moseys’ Robotics and Automation Solutions

Moseys’ Robotics and Automation Solutions

Here are some of the ways our Anaheim machine shop is using robotics and automation:

Machine tending

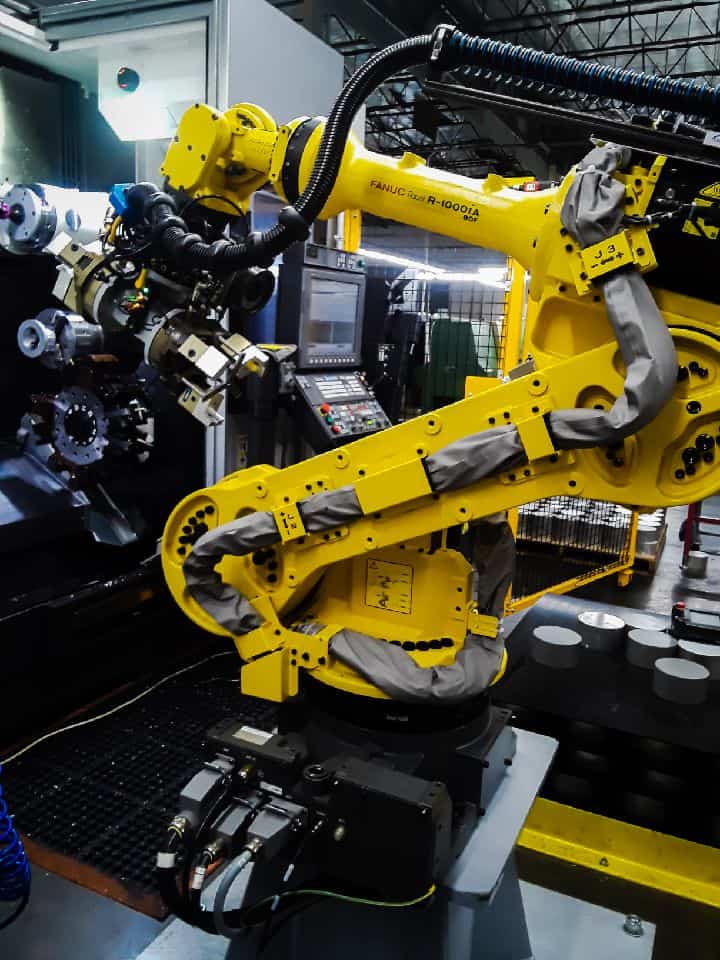

Machine tending involves using a robotic arm to load and unload a machine automatically. Moseys uses our two robotic arms to load raw materials into machines, remove finished parts from machines, palletize finished parts, and depalletize raw materials.

Bar loading and part conveying

We have two other systems that have bar loaders and part conveyors. Though no robot is involved, these systems function similarly to the robotic arm. The bar loader feeds 36” raw material bars into our lathe, and the lathe runs the parts. As the parts come out of the sub-spindle, they are ejected onto a conveyor, which runs to the back of the machine.

Pallet moving

When an individual loads a pallet (also called a tombstone) onto a horizontal mill, our pallet moving shuttle system collects the loaded pallet and places it into the storage rack until the machine is finished performing other operations. When ready, the system collects the pallet from the storage rack and loads it into the machine. Then, it brings the finished pallet out and puts it in a loading station where an individual can unload it and load it back up.

Next Up: Automating Inspection

Now that our Anaheim machine shop has successfully automated our CNC machining equipment, we’re looking ahead to other ways we can leverage automation and robotics. Next up is incorporating advanced automation into our inspection process.

Running parts lights out enables us to make more parts than ever before. Although this is a significant benefit overall, it poses a challenge for our inspection team because a) they have more parts to inspect, and b) they’re not there overnight when some parts are running to perform in-process inspections. When they arrive at the shop in the morning, they must collect the parts and perform meticulous inspections.

We have plans to streamline this process by implementing a CMM (coordinate measuring machine) on the shop floor that automates in-process inspections. We’ll then be able to inspect parts more frequently and at a higher rate than the basic AQL sampling size.

Our Anaheim Machine Shop Is Committed to Your Satisfaction

There is so much uncertainty in manufacturing, and so much that can feel out of customers’ control. But when you partner with Moseys, you can be certain that we’re doing whatever we can to provide high-quality parts at a reasonable price. Request a quote to work with us.