One of the processes that have set the manufacturing community abuzz in recent years is the rise, and continued development, of 3D printing.

Before 3D printing, CNC or Computer Numerical Control machining was the main way to manufacture three-dimensional parts.

Both 3D printing and CNC machining are able to employ a variety of materials, including:

- Metals like Aluminum

- Plastics

- Polymers

The type of manufacturing method you’ll want to use is highly variable. Some of the factors that help determine the best method to use are:

- Type and amount of materials required

- Geometric complexity and size

- Volume needed

- How quickly the part is needed

- End-use

- Budget

Considering the factors above may help when choosing a manufacturing method. Some obvious advantages and disadvantages can be found when using a 3D printer vs CNC machining. But first, let’s check out how they were developed.

CNC vs 3D Printing: History and Technology

3D Printing Origin

Plastic and metal 3D printing has been around since Charles Hull invented the first SLA or “Stereolithography” Machine in 1987. In its first iteration, SLA 3D printing used photochemical processes to form layers of polymers into objects.

3D Printing Today

Since the ’80s, 3D printing has rapidly expanded to include:

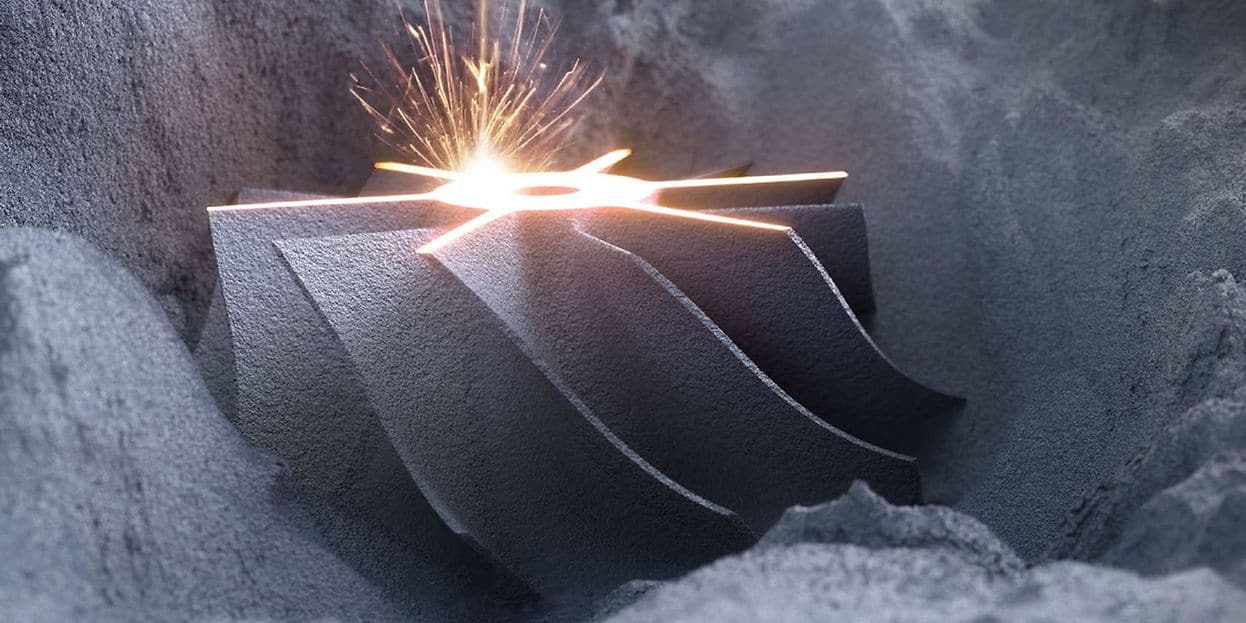

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Digital Light Process (DLP)

- Multi Jet Fusion (MJF)

- PolyJet

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

All of these types of 3D printing create parts in a layer-by-layer fashion, but the method and materials used may differ. Materials include plastic filaments, resins, sand, and metal powders. The base material used in printing is exposed to an energy source that solidifies the layers.

CNC Machining Origin

CNC machining has been around since the 1940s when John T. Parsons created the first Numerical Control machine to produce parts for helicopters. He used an IBM 602A multiplier (an electromechanical calculator that read and produced punch cards) to calculate data points and then fed the cards into a swiss jig borer, essentially “programming” the system.

| Need CNC Machining Experts to Create Your Next Precision Component?Talk to us today and get a timeline for delivery established right away.[Get a Quote] |

CNC Machining Today

Today, CNC machining is highly technical, using CAD (Computer-Aided Drafting/Design) and CAM software (Computer-Aided Manufacturing) to program state-of-the-art machinery. Different tools and speeds are used for producing parts from a myriad of materials. Some of the tools include:

- Milling machine

- Lathe

- Router

- Welder

- Grinder

- Laser or waterjet cutter

- Sheet metal stamping machine

- Robots

CNC Machining uses the tools above to cut parts from wood, metals, plastics and more.

CNC Machining vs 3D Printing: How They Differ

The main difference between the two methods is that 3D printing is an additive manufacturing process that builds parts by stacking material layer by layer and CNC machining is a subtractive process that cuts away from a larger block of material to create smaller parts. This presents some inherent strengths and weaknesses.

3D Printer vs CNC Machine: Strengths and Common Uses

3D Printer Strengths

- 3D printing can create cost-effective, complex parts quickly at lower volumes.

Common Use: 3D printing is ideal for creating prototypes quickly for fit checks. It is also good for producing tooling or other low-volume requirements.

- 3D printing produces non-structural, low-weight parts with ease.

Common Use: Great for creative items, medical parts, small piece parts, phone cases, art and games. Although this method has expanded into 3D printing metals and other materials, plastic is still the most widely-printed, low-cost option.

- Less supervision and upfront investment are usually required.

Common Use: 3D printers are often used by individuals or small businesses creating low-volume and custom parts. Aside from when they require support structures, printers can be programmed, started and left alone.

- 3D printing is able to make parts with complex geometries that are difficult to replicate in other ways.

Common Use: 3D printing is able to help with the consolidation of multiple parts into one printed component.

CNC Machining Strengths

- CNC has incredible accuracy and tight tolerances at high volumes.

Common Use: CNC produces precise, technical parts for industries requiring stringent quality control. Surgical equipment, firearm bodies and slides, engines, gears and other tools are made with CNC machining.

- CNC machines are able to produce a wide range of specific surface finishes without further processing.

Common Use: Parts may need to be smooth and free of even minuscule obstructions to connect to other parts in a system or structure.

- CNC routers can cut metals easily to make large, weight-bearing, structural parts.

Common Use: CNC machining cuts aluminum to create strong, metal parts for aircraft and other types of transportation vehicles.

- Per-part production is quick and programming and setup can be reused.

Common Use: CNC machining is often used when companies request mass production of goods to scale, often in the hundreds and thousands.

CNC vs 3D Printer: Weaknesses (What to Avoid)

3D Printer Weaknesses

- Currently more focused on plastics as 3D printers for metals are still quite expensive

- Limited in speed and accessibility at high volumes

- Can not create parts as large as CNC machines at this point in time

- May have additional processing requirements due to roughness after printing

CNC Machining Weaknesses

- Creates more waste than 3D printing processes due to the subtractive manufacturing method of removing material

- Can not work with superalloys or thermoplastic polyurethane

- Requires skilled operators

CNC and 3D printing are both making notable advancements. Both types of manufacturing methods can be found in different stages of product design and development. Considering the factors, strengths and weaknesses listed above can help make your choice of manufacturing method easier.

Talk to us today to see whether 3D printing or CNC machining is right for your project.